|

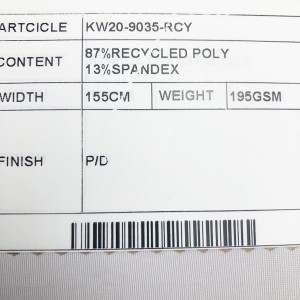

PRODUCT CATEGORY |

Swimwear Fabric |

|

ITEM NO |

KW20-9035-RCY |

|

Supply Type |

Make-to-Order |

|

Material |

87%Recycled Poly 13%Spandex |

|

Weight |

195GSM |

|

Width |

155CM |

|

Finish |

P/D |

|

Sample time |

5-7 days |

|

Feature |

P/D / Wicking/ High Stretch / Soft Handfeel |

|

Use |

Garment/ Track suit / Sportswear/ Swimwear/ T-shirt |

|

Market |

USA/Canada/Australia/UK/Germany |

|

Certificate |

GRS/SGS/OEKO-TEX STANDARD 100 |

|

Place of Origin |

China (Mainland) |

|

Packaging Details |

packing in rolls with plastic bags or base on your requirement |

|

Payment |

L/C T/T |

|

Print Patter/ Custom design |

Sublimation print & Digital print as custom design |

|

MOQ |

1000M |

|

C0-Brand |

Adidas/ Nike/ H&M/ Vans/ Decathlon |

|

Sample Service |

Free |

|

Customized Pattern |

Support |

|

Our Service & Advantages |

Free sample available. Customized pattern, width, weight. Quick delivery. Competitive price. Good sample development service. Strong R&D and Quality Control team. |

|

Process Of Production |

1.Contact us 2.Developments 3.PO&PI 4.Bulk production 5.Payment 6.Inspection 7.Delivery 8.Long partner |

In the summer, everyone will relieve the heat by swimming, and swimwear has become a necessity for swimming. A suitable swimsuit can give us a better experience when swimming, and the quality of swimwear is mainly due to swimwear fabrics. The type and quality of the swimsuit are determined.

Unlike polyester, recycled polyester uses PET as the raw material. This is the same material that is used in clear plastic water bottles, and recycling it to create the fabric prevents it from going to landfill. The steps involved in the production process are as follows.

1. The collected PET bottles are sterilized. dried and crushed into small chips.

2. The chips are heated and passed through a spinneret to form strings of yarn

3. This yard is wound up in spools.

4. The fiber is then passed through a crimping machine to create a fluffy wooly texture.

5. This yarn is then baled, dyed, and knitted into polyester fabric.

This process of converting PET into recycled polyester requires much less energy than in the case of normal polyester. It takes 33-53% less energy. Isn’t that a huge difference? There are two main advantages to this process:

-Using more recycled polyester reduces our dependence on petroleum as the raw material or our fabric needs.

-Diverting PET bottles for this process reduces landfill, and thus less soil contamination, air, and water pollution.

Another benefit is that the garments created from recycled polyester can be recycled again and again with no degradation of quality, allowing us to minimize wastage. This means garment manufacture could potentially become a closed-loop system, polyester could forever be reused and recycled! Something you cannot say for a lot of other fibers. The nonbiodegradability of polyester could be a good thing, not bad!

FAQ

Ordering Information

Payment: We usually accept T/T 30%

Packing: In roll packing with tubes inside and plastic bags outside or according to customers’ request.

Delivery Time:

LAB DIPS takes 2-4 days;

STRIKE OFF takes 5-7 days;

10-15days for sample development.

Plain dye color: 10-15 days.

Printing design: 5-10 days.

For an urgent order, could be faster, please send an email to negotiate.

Why choose us?

We buy yarn, produce greige fabric and dying or print by ourselves, that makes a more competitive price and faster delivery.