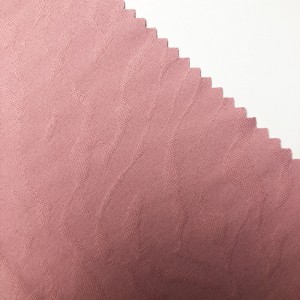

| PRODUCT CATEGORY | Yoga Wear FABRIC | |||||

| ITEM NO | KWC21-4081 | |||||

| Supply Type | Make-to-Order | |||||

| Material | 88% Polyester 12% Spandex | |||||

| Weight | 250GSM | |||||

| Width | 73/75″ | |||||

| Density | Customized | |||||

| Yarn | 40D | |||||

| Feature | Breathable/High Elasticity/High Quality High Color Fastness |

|||||

| Use | Swimwear/Garment/Sportswear | |||||

| Market | USA/Canada/Australia/UK/Germany | |||||

| Certificate | RSG/SGS | |||||

| Place of Origin | China (Mainland) | |||||

| Packaging Details | packing in rolls with plastic bags or base on your requirement |

|||||

| Payment | L/C T/T | |||||

| Print Patter/ Custom design | Sublimation print & Digital print as custom design | |||||

| MOQ | 100 | |||||

| C0-Brand | Adidas/Nike/H&M/VANS/Decathlon | |||||

| Sample Service | Free | |||||

| Customized Pattern | Support | |||||

| OUR SERVICE & ADVANTAGES | Free sample available. Customized pattern, width, weight. Quick delivery. Competitive price. Good sample development service. Strong R&D and Quality Control team. |

|||||

| Process Of Production | 1.Contact us 2.Developments 3.PO&PI 4.Bulk production 5.Payment 6.Inspection 7.Delivery 8.Long partner |

|||||

First of all, please understand these three concepts: plain weave, twill weave, and satin.

Plain weave: The fabric woven with plain weave is called plain weave. That is, the warp yarn and the weft yarn are interlaced every other yarn (that is, the yarn is 1 up and 1 down). This kind of cloth is characterized by many interweaving points, firm texture, scratching, and smooth surface. High-end embroidery fabrics are generally plain weave fabrics.

Twill: Warp yarn and weft yarn are interwoven once at least two yarns, that is, 2 up and 1 down or 3 up and 1 down. Adding warp and weft interlacing points to change the structure of the fabric, collectively referred to as twill fabric. The characteristic of this kind of cloth is that it is relatively thick and has a strong sense of three-dimensional structure. There are 30 branches, 40 branches, and 60 branches.

Satin cloth: warp and weft are interwoven once at least three yarns, so the satin weave makes the fabric denser, so the fabric is thicker. Satin weave products are more expensive than similar plain weave and twill weave products, and the fabric surface is smooth, fine and shiny. Plain weave, twill weave and satin are the three basic ways of weaving warp and weft. There is no specific difference between good and bad here. Each has its own characteristics. Among them, satin is definitely the finest of pure cotton fabrics.

Let’s talk about tribute in detail.

Satin satin must distinguish four concepts: satin, satin strip, satin grid, satin jacquard.

What kind of fabric is satin? In fact, through the introduction just now, you have already understood that “plain weave, twill, and satin” are all fabrics, not specific fabrics.

The most common satin fabric is striped satin, referred to as satin strip. The texture is a horizontal strip extension (see picture). Using the process of weaving first and then dyeing, this kind of fabric is generally solid color. Can not afford the ball, not easy to fade.

There is also a kind of satin, called satin grid, which is also a solid color and is a lattice type (see picture).

Satin strips and satin grids are generally the raw materials for hotel bedding. They are inexpensive and luxurious and practical. Satin strips and satin grids are also used to make home kits, but they are far less popular than satin jacquard fabrics.

Jacquard fabric: The pattern on the fabric is woven, not ordinary printing, nor embroidery. When the fabric is weaving, the warp and weft structure changes to form a pattern, the yarn count is fine, the needle thread density is high, it is not deformed, does not fade, and has a good sense of comfort. Jacquard is very popular in the market, and satin bedding looks high-grade and tasteful. To distinguish the quality of satin, compare the yarn count and density.

The satin also talks about the yarn count. Let’s talk about the count first, which is what we often see 30, 40, 60, etc.! For example, some friends call it 30S for 30, it is the same, there is no difference! So what exactly is count? I understand it this way:

Count is the standard of yarn thickness. For example, one gram of cotton can be made into 30 yarns of 1 meter, that is 30 yarns, and one gram of cotton can be made of 40 yarns of 1 meter long, that is 40 yarns; one gram of cotton can be made into 60 yarns. A yarn with a length of 1 meter is 60 yarns. In fact, the higher the yarn count, the finer the yarn. The thinner the yarn is to weave, the softer and more comfortable the cloth will be. However, high-count fabrics require high-quality raw materials (cotton), and they also have high requirements for spinning mills and textile weaving mills, so the cost of fabrics is relatively high. High yarn count cloth is not suitable for bedding because it is too thin!

In addition to the production of yoga fabrics, we also have swimwear, beach pants, sportswear, running wear, ski wear, mountaineering wear fabrics.Welcome to consult us

FAQ:

Ordering Information

Payment: we usually accept T/T 30%

Packing: In roll packing with tubes inside and plastic bags outside or according to customers’ request.

Delivery Time

LAB DIPS takes 2-4 days; STRIKE OFF takes 5-7 days. 10-15days for sample development.

Plain dye color: 10-15 days.

Printing design: 5-10 days.

For urgent order, could be faster, please send email to negotiate.

Why choose us/FEIMEI?

We buy yarn, produce greige fabric and dying or print by ourselves, which makes more competitive price and faster delivery.