|

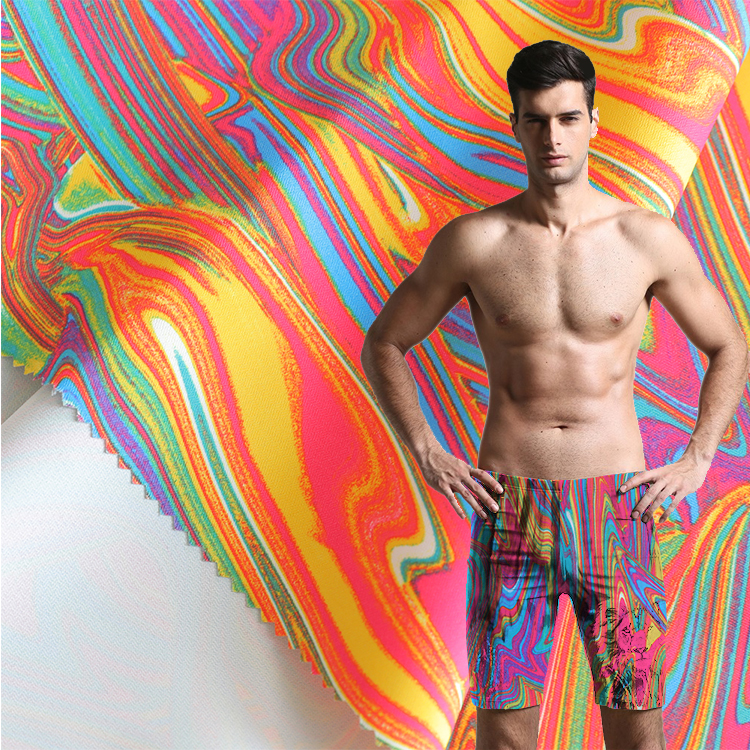

PRODUCT CATEGORY |

Boardshort Fabric |

|

ITEM NO |

KWS20-4043-PRT |

|

Supply Type |

Make-to-Order |

|

Material |

88%POLY 12%Spandex |

|

Weight |

180GSM |

|

Width |

57’’58’’ |

|

Finish |

PRT+W/R |

|

Sample time |

5-7 days |

|

Feature |

Waterproof/ DWR/ High Color Fastness |

|

Use |

Garment/ Board short/ Boardshort/ Beach pants |

|

Market |

USA/Canada/Australia/UK/Germany |

|

Certificate |

GRS/SGS/OEKO-TEX STANDARD 100 |

|

Place of Origin |

China (Mainland) |

|

Packaging Details |

packing in rolls with plastic bags or base on your requirement |

|

Payment |

L/C T/T |

|

Print Patter/ Custom design |

Sublimation print & Digital print as custom design |

|

MOQ |

1000M |

|

C0-Brand |

Adidas/ Nike/ H&M/ Vans/ Decathlon |

|

Sample Service |

Free |

|

Customized Pattern |

Support |

|

Our Service & Advantages |

Free sample available. Customized pattern, width, weight. Quick delivery. Competitive price. Good sample development service. Strong R&D and Quality Control team. |

|

Process Of Production |

1.Contact us 2.Developments 3.PO&PI 4.Bulk production 5.Payment 6.Inspection 7.Delivery 8.Long partner |

Waterproof fabrics are fabrics that are inherently or have been treated to become, resistant to penetration by water and wetting. The term “waterproof” refers to conformance to a governing specification and specific conditions of a laboratory test method. They are usually natural or synthetic fabrics that are laminated to or coated with a waterproofing material such as rubber, polyvinyl chloride (PVC), polyurethane (PU), silicone elastomer, fluoropolymers, and wax. Treatment could be either of the fabric during manufacture or of completed products after manufacture, for instance by a waterproofing spray. Examples include the rubberized fabric used in Beachwear, softshell wear, and skiwear.

Textile printing is the process of applying color to fabric in definite patterns or designs. In properly printed fabrics the color is bonded with the fiber, to resist washing and friction. Textile printing is related to dyeing but in dyeing properly the whole fabric is uniformly covered with one color, whereas in printing one or more colors are applied to it in certain parts only, and in sharply defined patterns.

Wuxi Kuanyang Textile Technology CO., Ltd has a history of 25 years, specializing in the development and sales of sublimation printing fabrics and digital printing fabrics.

So, what is sublimation printing all about then? We’re here to explain the actual nitty-gritty details, how it makes a thing colorful, the process.

Firstly, your design is printed onto a specialist transfer paper. It is printed as a mirror image, using specialist dye-sub inks.

These are water-based inks that have less of an environmental impact than harsher chemical inks. After that, the transfer is lined up with the fabric, and a combination of heat and pressure are applied. This causes the inks to transition from their current solid form, directly into a gas.

The inks then penetrate the fibers of the material and are permanently bonded to the fibers. The result is a high-definition print with an extremely intricate level of detail.

FAQ

Ordering Information

Payment: We usually accept T/T 30%

Packing: In roll packing with tubes inside and plastic bags outside or according to customers’ request.

Delivery Time:

LAB DIPS takes 2-4 days;

STRIKE OFF takes 5-7 days;

10-15days for sample development.

Plain dye color: 10-15 days.

Printing design: 5-10 days.

For an urgent order, could be faster, please send an email to negotiate.

Why choose us?

We buy yarn, produce greige fabric and dying or print by ourselves, that makes a more competitive price and faster delivery.