|

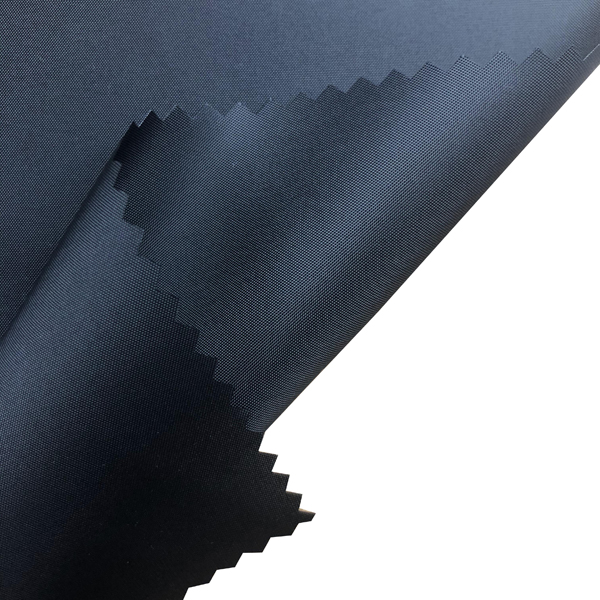

PRODUCT CATEGORY |

Functional Fabric |

|

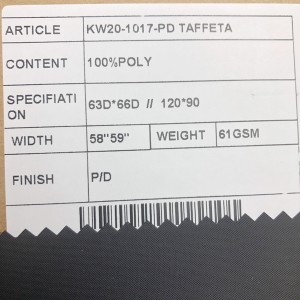

ITEM NO |

KW20-1017-RW+PUC |

|

Supply Type |

Make-to-Order |

|

Material |

100%POLY |

|

Weight |

64 GSM |

|

Width |

57’’58’’ |

|

Finish |

Raw White+ W/R(70/3)+PU Clear Coating (600mm) +Anti Static |

|

Sample time |

5-7 days |

|

Feature |

Waterproof, bonded fabric,Anti Static |

|

Use |

Garment/ Urban wear/ Functional fabric /Coat/Jacket |

|

Market |

USA/Canada/Australia/UK/Germany |

|

Certificate |

GRS/SGS/OEKO-TEX STANDARD 100 |

|

Place of Origin |

China (Mainland) |

|

Packaging Details |

packing in rolls with plastic bags or base on your requirement |

|

Payment |

L/C T/T |

|

Print Patter/ Custom design |

Sublimation print & Digital print as custom design |

|

MOQ |

1000M |

|

C0-Brand |

Adidas/ Nike/ H&M/ Vans/ Decathlon |

|

Sample Service |

Free |

|

Customized Pattern |

Support |

|

Our Service & Advantages |

Free sample available Customized pattern, width, and weight competitive price fast response and professional suggestion on all inquiries punctual delivery time 25 more years of experience in the field of fabrics |

|

Process Of Production |

1.Contact us 2.Developments 3.PO&PI 4.Bulk production 5.Payment 6.Inspection 7.Delivery 8.Long partner |

The use of functional fabrics is versatile and becoming common in several industries such as automotive engineering, aerospace, aeronautics, architecture, healthcare, construction engineering, military, and security.

Functional textiles are fabrics with a set of integrated functions of controlling or adjusting according to their application. Such textiles are usually produced with a focus on function rather than on aesthetics. Smart textiles are characterized by functionality, versatility, compatibility, flexibility, and interactivity. Functions could include temperature regulation, humidity control, health monitoring, sports training, position tracking, protection clothing, abrasion resistance, anti-bacterial properties, moisture absorption, quick-drying functions, and many more.

Several technical and commercial challenges lie ahead to realize the full promise of “smart” textile-based devices. From an engineering mechanics perspective, textiles are multi-scale, extensible structures – they can be nanometers or kilometers in length. Textile structures can be produced with relatively higher levels of control over local morphology than achievable in 3D printing processes, where microstructure formation is governed by the complex kinetics of melting & solidification.

Furthermore, advances in electrospinning, fiber drawing, extrusion enable the fabrication of unique fiber and yarn materials with highly desirable sets of intrinsic properties. However, system integration remains a major challenge.

The global functional textile market is geographically divided into five key regions including North America, Latin America, Europe, Asia-Pacific, and Middle East & Africa. Europe holds a maximum share of the functional textile market in terms of production. The fact is due to the vast growth of the textile and apparel industry in Germany, France, Italy, the UK, and also the high-tech developments. Also, North America holds a healthy market in terms of production for functional textile comparative to Europe. The Asia Pacific and MEA offers extensive opportunity for functional textile market. Malaysia, Taiwan, South Korea, Japan, and Turkey are anticipated to be a promising market for functional textile market growth prospectus.

FAQ

1. Are you a factory or trading company?

We are a factory and we have a professional team of workers, Designers, and inspectors.

2. How to get a sample?

We will prepare free samples for you. For the first-time cooperation, the postage charge would be by the customer’s account. After placing orders, we will send free samples.

3. How long to deliver the products?

LAB DIPS takes 2-4 days;

STRIKE OFF takes 5-7 days;

10-15days for sample development.

Plain dye color: 10-15 days.

Printing design: 5-10 days.

For an urgent order, could be faster, please send an email to negotiate.