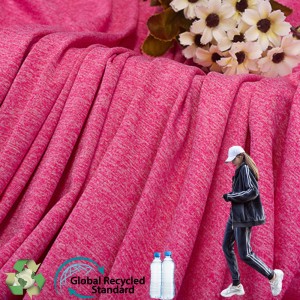

| PRODUCT CATEGORY | SPORTSWEAR FABRIC | |||||

| ITEM NO | KWS20-8011 | |||||

| Supply Type | Make-to-Order | |||||

| Material | 90% Polyester 10% Spande | |||||

| Weight | 2500GSM | |||||

| Width | 73/75″ | |||||

| Density | Customized | |||||

| Yarn | 40D | |||||

| Feature | Breathable/High Elasticity/High Quality High Color Fastness |

|||||

| Use | Swimwear/Garment/Sportswear | |||||

| Market | USA/Canada/Australia/UK/Germany | |||||

| Certificate | RSG/SGS | |||||

| Place of Origin | China (Mainland) | |||||

| Packaging Details | packing in rolls with plastic bags or base on your requirement |

|||||

| Payment | L/C T/T | |||||

| Print Patter/ Custom design | Sublimation print & Digital print as custom design | |||||

| MOQ | 100 | |||||

| C0-Brand | Adidas/Nike/H&M/VANS/Decathlon | |||||

| Sample Service | Free | |||||

| Customized Pattern | Support | |||||

| OUR SERVICE & ADVANTAGES | Free sample available. Customized pattern, width, weight. Quick delivery. Competitive price. Good sample development service. Strong R&D and Quality Control team. |

|||||

| Process Of Production | 1.Contact us 2.Developments 3.PO&PI 4.Bulk production 5.Payment 6.Inspection 7.Delivery 8.Long partner |

|||||

Sports clothing with the characteristics of absorbing sweat and quick-drying or moisture wicking can be called “Refreshinggarments”, which provides a comfortable feeling for competitors and creates great achievements on the sports field.

The design concept of this type of clothing comes from the capillary phenomenon of trees, such as the multi-layer polyester knitted Fieldsensor, whose inner layer is thick denier polyester yarn, which is in direct contact with the skin, and the outer layer is hydrophobic fine denier polyester yarn. The dense surface structure can accelerate the effect of perspiration. Cubesensor and Coolmagic woven fabrics, Aerosensor double-sided warp knitted fabrics, with similar concepts, develop more differentiated functions.

In swimming and ski jumping competitions, due to fierce competition, the gap is often within 0.01 seconds. Therefore, for the needs of such athletes, low-resistance functions have emerged. For swimming suits, there are Nylon Superfine Dan High-needle (32G) double-sided warp knitted fabrics blended with nylon yarn and elastic yarn, such as Toray’s Acquapin fabric, can reduce frictional resistance in water by 10%.

Another product, Acquaspec, has better functionality and can reduce resistance by 15%. It is made of polyester superfine denim through surface finishing. Other companies such as Descente use corrugated processed silk to form very fine grooves on the surface of the fabric to reduce frictional resistance in water. The same design concept is used for air fluid to reduce the resistance of ski jumpers in the air.

Dimplex fabric is a joint collaboration between Descente and Eschler. The surface of the ski jump fabric is formed into a convex shape with corrugated processed silk, so that the athletes can minimize the air resistance during the start, take-off and air flight stages.

In competitions, athletes often have fierce and rough movements, such as fast slips, collisions, and collisions. Dynamonus fabric is a blend of high-strength polyester staple fiber yarn and 5~15% P-aromatic polyamide fiber (high-strength fiber). It has excellent heat resistance and can resist friction, abrasion and mountaineering. Time, prevent being cut by the sharp angle of the rock.

In addition to sportsmen, consumers in general are also beginning to be concerned about the functionality of their sportswear? This demand has gradually expanded. Mr.K.Hayakawa put forward a novel view on the future. The ancient aesthetics are presented in “nude”, which means that the design of sportswear in the future must be shaped according to the human body structure, so that the resistance and restraint force can be minimized during exercise, looking forward to the future New products can respond to more diverse needs.

In addition to the production of yoga fabrics, we also have swimwear, beach pants, sportswear, running wear, ski wear, mountaineering wear fabrics.Welcome to consult us

FAQ:

Ordering Information

Payment: we usually accept T/T 30%

Packing: In roll packing with tubes inside and plastic bags outside or according to customers’ request.

Delivery Time

LAB DIPS takes 2-4 days; STRIKE OFF takes 5-7 days. 10-15days for sample development.

Plain dye color: 10-15 days.

Printing design: 5-10 days.

For urgent order, could be faster, please send email to negotiate.

Why choose us/FEIMEI?

We buy yarn, produce greige fabric and dying or print by ourselves, which makes more competitive price and faster delivery.